The report also notes that hospitals, which employ 5 million people nationwide, could be facing uncertain times as their financial health falters and the ability to borrow funds for improving facilities and updating technology is squeezed.ĭespite these seemingly insurmountable challenges, there is a viable solution that healthcare administrators can implement to optimize their existing, though dwindling, resources and enable their organizations to economize through greater efficiencies and waste reduction: the Toyota Production System (TPS). This is evidenced by the AHA Report on the Economic Crisis: Initial Impact on Hospitals (2008). Even with the government’s substantial investment in information and decision-support technology and other patient-safety initiatives to reduce these types of medical errors and oversights, healthcare providers are being pressured to do even more with even less than before. Many feel compelled to cut valuable staff and services. This development and CMS pay-for-performance rewards are further incenting hospitals to minimize errors and maximize performance. The Centers for Medicare and Medicaid (CMS 2008) have added fuel to the fire by no longer paying for 11 “reasonably preventable never events,” leaving hospitals to foot the bill. By promoting waste reduction, quality, accountability, pay-for-performance, evidence-based medicine, modernization/automation, workflow optimization, core measures, and transparency, the country is embracing the tenets of the Toyota Production System. New federal legislation will likely influence how healthcare will be managed and compensated in this new era. This lean expert has previously worked at Toyota, Airbus, and Wrike and is dedicated to helping teams across the world develop a culture of non-stop improvement.A transformation to 21st century healthcare system is dramatically impacting patient safety and quality healthcare. To learn what it is, register for our webinar on ‘ How Toyota Really Works (Secrets behind TPS) ’ hosted by Errette Dunn, founder and CEO of Rever, a digitized kaizen platform for industrial companies. There is a powerful quality tool that comes from Kanban. The accountability and responsibility that comes with this pushes them to think creatively and efficiently. Kanban enables employees to operate the TPS by taking responsibility for managing their own jobs and, in a sense, helps everyone become a co-manager of the factory.

The real star of the Toyota System is enabled by Kanban. Try to avoid seeing Kanban as a star of the Toyota Production System. This helps create an open channel to try new ideas and processes. Most importantly, with solid job security, employees are willing to experiment and make mistakes. The time spent training a new employee is a waste in comparison to keeping employees furloughed. They also forget that Toyota differs from them in two significant ways: the benefit of guaranteed employment and thus allowing employees to learn from their mistakes.Įven in a recession, Toyota rarely lets go of their employees. Most organizations don’t have the right culture and aren’t ready to make that same transition. Toyota has decades of experience in various disciplines of lean and has a strong, mature lean program. Most companies make a fatal mistake of trying to compare themselves against Toyota.

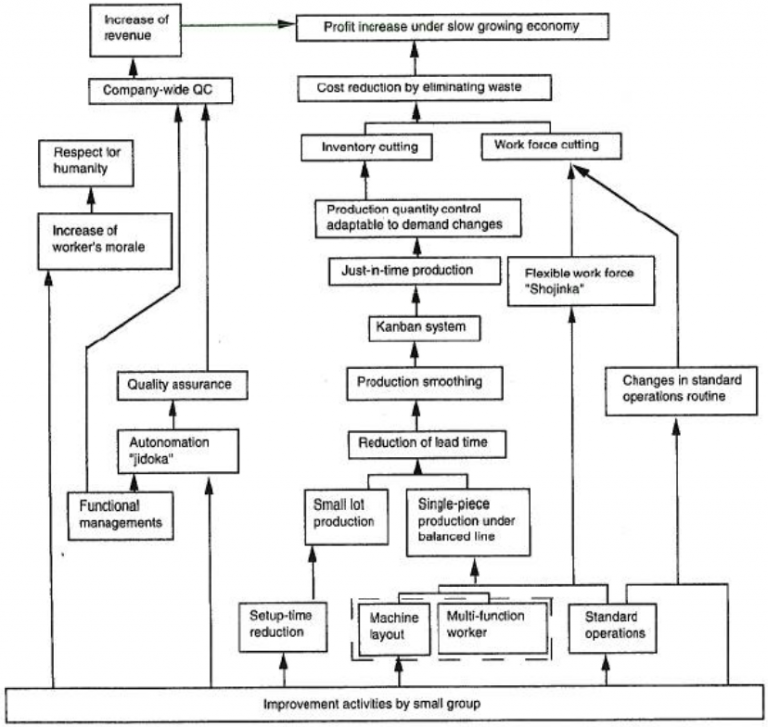

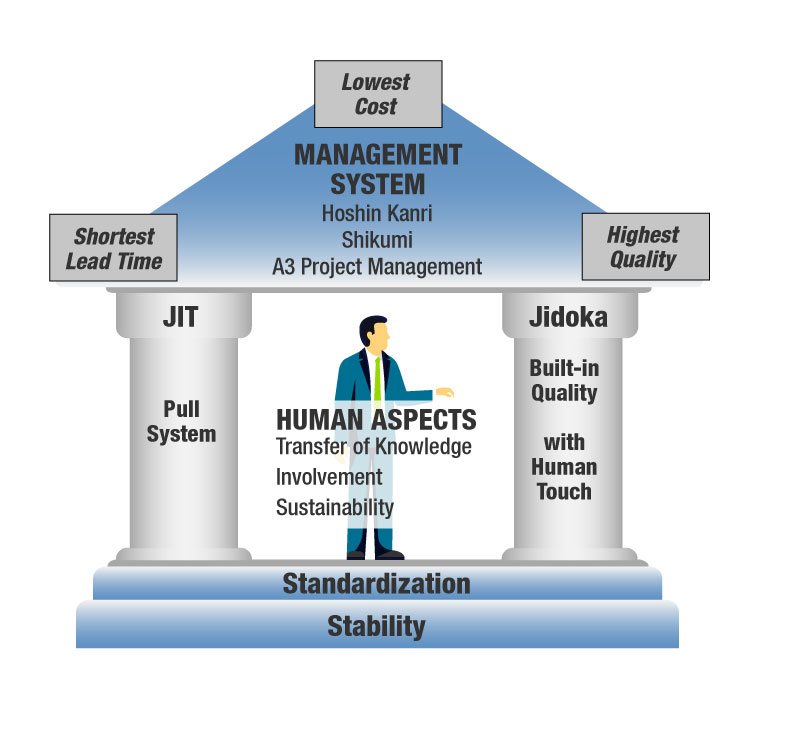

Jidoka loosely translates to ‘automation with a human touch,’ meaning when a machine detects any problems during manufacturing, it’ll automatically cease production without any human intervention or supervision. There are two ways in which TPS achieves this goal: just-in-time delivery and “jidoka.” Just-in-time refers to producing only what is needed when it is necessary and reducing inventory. TPS achieves this goal by eliminating overburden (muri), inconsistency (mura), and waste (muda) to improve production processes. The Toyota Production System is centered around the simple goal of saving time and reducing cost to deliver greater value to the customer. We dive into an overview of TPS, what you should not take away from Toyota, and most importantly, the secrets behind its success. But why is everyone in the lean manufacturing world obsessed with Toyota? It might have something to do with how Toyota toppled GM to become the world’s #1 auto manufacturer, or how Toyota is the world’s most valuable car brand and car maker, with over 120 billion dollars ahead of all other competitors in terms of market cap value. Every lean practitioner is well versed in the classics: Lean, Six Sigma, but most notably: the Toyota Production System.

0 kommentar(er)

0 kommentar(er)